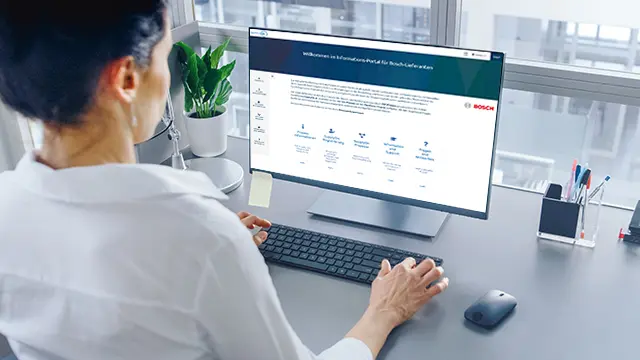

Information for business partners

Cooperation on an equal footing: transparency, mutual trust, and fairness define the business relationship between Bosch and its partners. In the spirit of the founder, these values are at the core of every company decision and every action. For mutual success — today and in future.

Foundation of our cooperation: Responsibility and sustainability

For Bosch, the values responsibility and sustainability have always been intertwined. Ethically correct and resource conserving business conduct is the basis for a responsible business relationship.

Purchasing Terms and Conditions

The contractual basis for the cooperation between Bosch and partners in selected regions is listed below.

Please chose the region, in which the respective company of the Bosch-Group (your contracting party) is located. You will find a link to the applicable Bosch Purchasing Terms and Conditions.

Additional country-specific regulations may apply.

Furthermore, irrespective of the region, the Global Supplementary Terms and Conditions apply.

Global Supplementary Terms & Conditions

Logistics: Regulations and Standards

Clear rules and agreements make life easier. The supplier guidelines for Logistics help to improve the supplier relationships.

Supplier guidelines for Logistics

- Previous version 5.0:

Download document - Major changes V6 compared to V5:

Download document

Additional requirements for deliveries to Mobility Aftermarket (MA)

- Additional requirements of MA to Supplier Logistics Manual (EMEA)

Download document - Additional requirements of MA to Supplier Logistics Manual (World)

Download document - Warehouse Specifics MA

Download document - Delivery Documents MA

Download document

Requirements of Bosch for the implementation of the Global Transport Label (GTL) according to VDA recommendation 4994.

Following amendments of the supply chain manual logistics apply.

MAT-Label

- Standardized labeling of parts from suppliers with MAT-Label

- Specification of MAT-Label for Automotive Electronics (AE)

- Specification of MAT-Label for Final Tested Parts (AE)

Appendices to above documents for particular kinds of products:

In addition to the SupplyOn platform, Bosch also uses Classic EDI for data transfer.

Supplier and Carrier information about NGTM | Next Generation Transport Management

To access comprehensive information, please explore the following websites by region:

- European Land Transportation:

Welcome to the NGTM Info Portal for Bosch Suppliers in Europe | SupplyOn Support Center (EN, DE) - North American Land Transportation:

Welcome to the NGTM Info Portal for Bosch Suppliers in North America | SupplyOn Support Center (EN, ES)

Quality: Regulations and Standards

Quality as success factor: further requirements and information regarding quality management are listed below.

General quality documents

- Booklet 1 - Basic Concepts of Technical Statistics - Continuous Characteristics

- Booklet 2 - Basic Concepts of Technical Statistics - Discrete Characteristics

- Booklet 3 - Evaluation of Measurement Series

- Booklet 4 - Statistical Procedures, Formulas and Tables

- Booklet 5 - Statistical Tolerancing

- Booklet 6 - Evaluation of Field Data (DE)

Booklet 6 - Evaluation of Field Data (EN) - Booklet 7 - Statistical Process Control, SPC

- Booklet 8 - Measurement Uncertainty (DE)

Booklet 8 - Measurement Uncertainty (EN) - Booklet 9 - Machine and Process Capability (DE)

Booklet 9 - Machine and Process Capability (EN) - Booklet 10 - Capability of Measurement and Test Processes

- Booklet 11 - Design of Experiments (DoE)

- Booklet 13 - Methods of design for reliability, verification and validation

- Booklet 14 - Failure Mode and Effects Analysis FMEA

- Booklet 15 - Fault Tree Analysis - FTA

- Booklet 16 - Problem Solving

Specific quality documents

Supplier Quality Requirements

Cooperation for New Products

Change Management

- New Process for Supplier Initiated Change Request (SICR) - Overview

- Supplier manual for SICR process (Download)

- Direct link to the entry point for submission of a SICR

Supplier Quality Improvement Program

Supplier Quality Requirement

Cooperation for New Products

Change Management

- Part Change Notification (under rework)

- Postbox: ChangeNotificationsPOBox.BoschST@de.bosch.com

Supplier Quality Requirement